Overcoming Supercapacitor Challenges

Energy storage is traditionally associated with batteries to provide energy for electronic devices. However, supercapacitors are being increasingly installed to complement these batteries in Internet of Things (IoT) systems, wearables, renewable energy systems, uninterruptible backup power supplies, battery-supercapacitor hybrid energy storage systems, and energy harvesting. Using supercapacitors with other power sources like batteries and energy harvesters is a popular option to increase capability, capacity, and resilience.

Unlike batteries, supercapacitors are designed to charge and discharge high amounts of energy very quickly, offering a kind of rapid response that batteries and energy harvesters cannot offer on their own. This ability, coming from supercapacitors’ low internal resistance and high power density, helps smooth out power fluctuations to protect power supplies (like batteries) and the load.

For example, supercapacitors are well suited to absorb the energy captured in regenerative braking systems used in electric vehicles (from trains to cars). Then, the supercapacitor can also be discharged very quickly to assist in accelerating the vehicle.

Supercapacitors are the missing piece to highly efficient and resilient energy storage systems. Supercapacitors are faced with a few key challenges that have held them back in a variety of applications. These challenges are:

A low voltage rating per cell

A lack of physical space to install supercapacitors

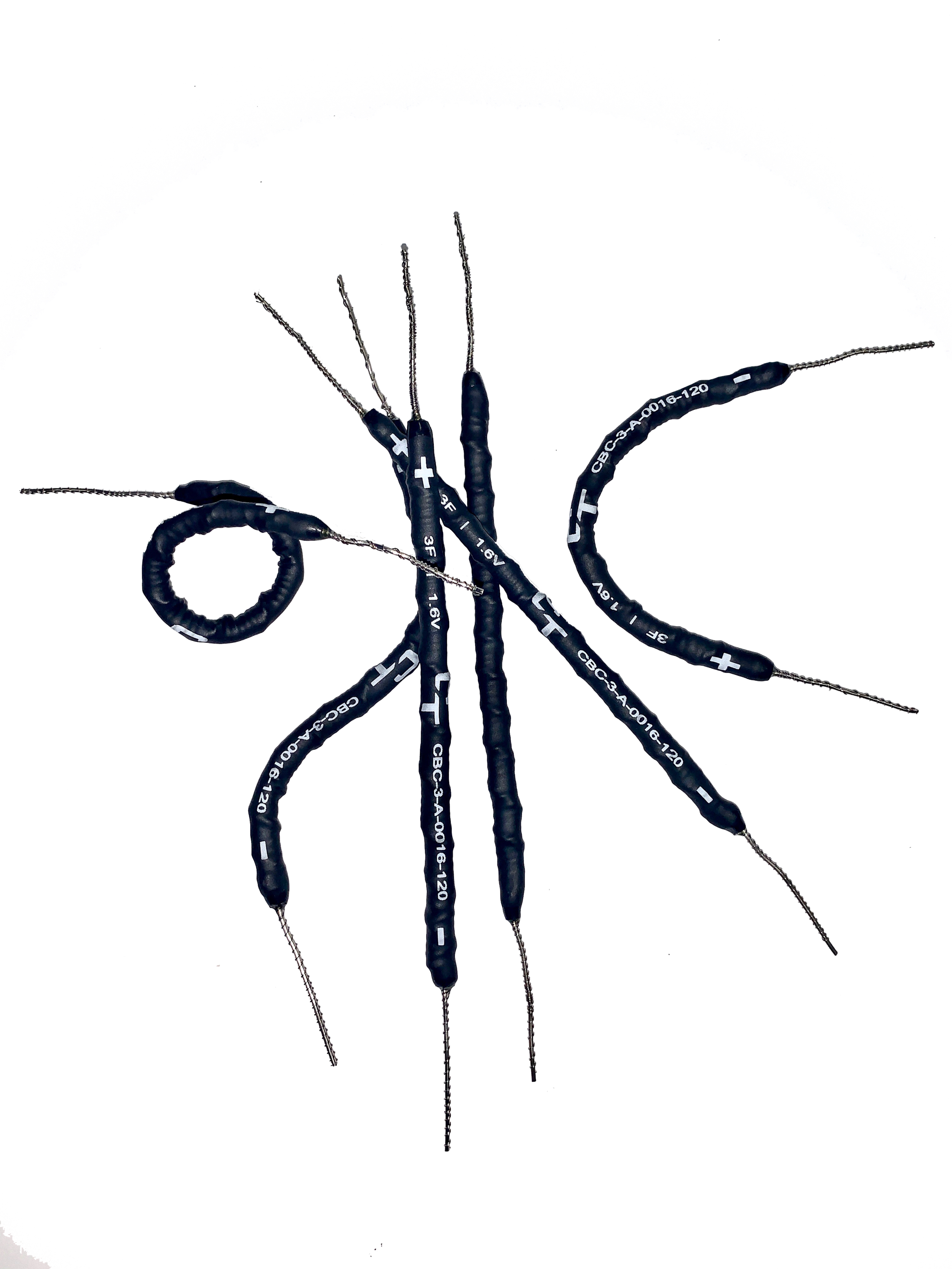

Capacitech’s Cable-Based Capacitor product line addresses these challenges by leveraging its highly innovative, globally recognized, wire-like and flexible form factor.

Capacitech’s Cable-Based Capacitor is a wire-shaped and physically flexible supercapacitor featuring over 3 Farads of capacitance. Its unique physical characteristics (form factor) offer engineers placement advantages.

Addressing Supercapacitors’ Low Voltage Rating

A single supercapacitor cell is typically rated between 1.4V and 3.5V. Even if a single cell meets requirements for energy storage capacity or peak power requirements, the system the supercapacitor is used in may operate at a higher voltage than a single cell can withstand. While an individual cell may not meet the requirements for an application, connecting several cells together in a module might.

This is a well known issue simply solved by connecting cells in series with one another, forming a module. Cells can also be connected in parallel to increase the capacitance, energy storage capacity, and peak power capability of the module. These concepts are true for the CBC as well as any other supercapacitor cell. More detailed information on how to design for CBC modules can be found here: Designing (flexible) Supercapacitor Modules with the CBC.

A supercapacitor’s voltage rating is largely limited by its electrolyte (a key component of the chemistry inside the supercapacitor). Until researchers develop a higher voltage rated electrolyte (which has been many years in the making and many more years to come), the current solution for supercapacitors’ low voltage rating is to build modules by connecting cells in series.

This solution creates a major problem of its own… Adding supercapacitor cells in series (forming modules) takes up a lot of space, creating a series of negative tradeoffs in order to utilize supercapacitors in a product or system.

This is where Capacitech’s CBC thrives, leveraging its unique form factor to hide supercapacitors in the product or system to alleviate those negative tradeoffs that come with the space traditional supercapacitors take up.

Space Saving Opportunities of Flexible Supercapacitors

Supercapacitors are passive electronic components. They are traditionally installed in two ways:

On a printed circuit board

Connected on a module, installed on a circuit board, placed in their own electronic enclosure / container that is connected to the product or system via wiring.

Passive energy storage devices should not dictate the size of a circuit board, the active electronics should. Yet, supercapacitors are often the largest component of a circuit board and dictate the size and shape of the final product. A tall and skinny supercapacitor forces a taller enclosure. A short and wide supercapacitor takes up significant space on the circuit board, making the product larger or keeping designers from adding other features and capabilities to their product.

The CBC frees supercapacitors from their restriction to two-dimensional circuit boards. The CBC reimagines energy storage systems, designed to use less surface area on the circuit board and flexible enough that it can be integrated into the wiring infrastructure of a product or system.

Instead of building supercapacitor modules on circuit boards, or adding an eye sore to the system through stand alone supercapacitor enclosures, hide the supercapacitor module into the product or system’s infrastructure with the flexible CBC supercapacitor.

With the CBC, designers can build a discrete and distributed network of supercapacitors to help miniaturize electronics and complement power sources like batteries or energy harvesters; whether that is integrating supercapacitors into the leads of an indoor solar cell for an IoT application, the wiring harness of an electric vehicle, or the photovoltaic wiring of a solar farm.

Conclusion

Every design has its own requirements for voltage, capacitance, charging and discharging speed, and many others and these come with their unique challenges. The CBC is just like any other supercapacitor. Its voltage rating can be increased using series connections. Unlike any other supercapacitor, the CBC can be hidden in the infrastructure of the product or routed through free space on circuit boards. This avoids negative tradeoffs such as giving up features or making the product bigger.